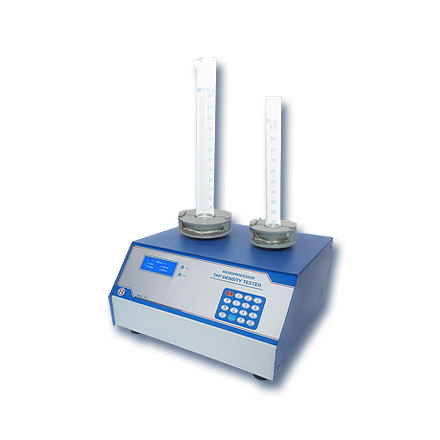

Tap Density Tester – 1951

Features

- Complies with USP, IP specifications

- Extremely useful for pharmaceutical labs

- Microprocessor based, easy to use

- 20 x 4 line alphanumeric LCD display with backlit

- 16 Soft touch membrane type keys

- Independent programmable setups for User & USP mode with storage

- Rs232 Printer attachment facility

- Automatically calculate result parameters like Tap Density, Initial Density, Compressibility Index and Hausner Ratio

- Automatically stores last Result

- Power Failure detection facility

- User friendly operation with menus & current status indicators.

Microprocessor Tap Density Tester, Model 1951 is a density measurement equipment used to measure tapped density of powders, as well as granulated or flaked materials by standardized and repeatable procedures. Instrument uses the latest microprocessor technology and advanced engineering techniques so as to give enhanced accuracy and reproducibility.

System is equipped with 4 line alphanumeric LCD display with backlit and 16 number of soft touch membrane type keys.

The unit is provided with two motorized platforms which allow for 14 ± 2.0 mm drop height for the USP Method I version, and a 3 ± 0.2 mm drop height for the USP Method II version. The motorized platforms consist of two cylinder holders with snap-lock mechanism designed to hold 100 ml and 250 ml cylinders. The simultaneous rotating and tapping motion minimizes any possible loss of mass during tapping down.

The instrument stores the test parameters, readings and results simultaneously in the memory which are retained even after the power is switched OFF. Provision has also been made for attachment of a printer so as to provide hard-copy printouts of test data, including the time, date and calculated results.

Specifications

| Test Methods | USP-I & USP-II |

| No. of Stations | 2 |

| Display | 20 x 4 Alphanumeric LCD |

| Keyboard | 16 Soft touch membrane keys, alphanumeric mobile keypad |

| Tap Height | USP-I: 14mm± 2mm, USP-II: 3mm ± 0.2mm |

| Taps/Minute | USP-I: 300± 15, USP-II: 250± 15 |

| No. of Tap Counts | 1 to 9999 |

| Type of Drive | Direct Drive with Stepper Motor |

| Printer Accessories | Attachment of RS232 printer with Serial interface |

| Standard Accessories | Cylinders 100 & 250ml (1 each) Cylinder holders for 100 & 250ml (1 each) |

| Electrical Supply | 230 V AC ± 10%, 50/60 Hz, 44VA |

| Dimensions (WxHxD) | 360x340x190 mm without holder |

| Weight | 15 Kgs |

Note : Specifications are subject to change due to continuous improvements.

ISO Certified

ISO Certified