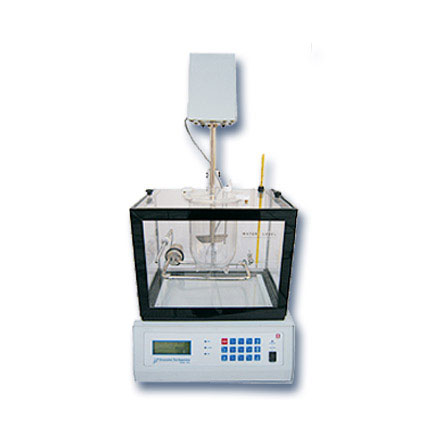

Microprocessor Dissolution Test Apparatus – 1912

Features

- Complies with USP, IP specifications

- Extremely useful for pharmaceutical labs

- Highly Accurate and Easy to Operate

- Programmable Stirrer Control

- 20 x 4 Line Alphanumeric LCD with Backlit

- 20 Setups Storage Facility

- 200 Samples Storage Facility

- Printer Attachment Facility

- Audio Visual Indicators for System Status

Microprocessor Dissolution Test Apparatus model 1912 is a solid state instrument designed for the determination of active drug ingredient in any pharmaceutical formulation, tablet or capsule as per USP and IP specifications. This apparatus evaluates adequate bio-availability and provides necessary information to formulate in the development of therapeutically optimum dosage forms. The instrument is designed and manufactured for pharmaceutical industry. It is used in quality control labs and R & D to determine compliance with the dissolution requirement of the Tablet and Capsule as per USP/IP standards.

Instrument uses the latest microprocessor technology and advanced engineering techniques so as to give enhanced accuracy and reproducibility. The system has user friendly prompts, which guide you throughout the measurement process.

Microprocessor Dissolution Test Apparatus is equipped with 4 line alphanumeric LCD display with backlit for displaying various test parameters and 15 soft touch membrane type keys with full numeric keypad that provides a convenient interface for entering numeric values. The samples being analyzed are automatically stored in the memory in different batch and sample numbers.

The instrument has the storage facility for 200 samples. It also has the facility for setting up 20 different test methods using Routine and Sustain modes which are retained in the memory even when the power is switched OFF. Provision has also been made for attachment of any dot matrix printer with centronics interface so that any of the stored setups/results can be printed.

The unit is provided with 1 unbreakable dissolution vessel with cover, having necessary arrangement to hold temperature sensor and the same is placed in the sturdy, acrylic water bath. The large spread out stainless steel heater ensures perfectly uniform heating. The instrument has dual channel temperature system with sensors to monitor the test temperature of dissolution vessel as well as water bath temperature.

The Stirrer unit is attached by single column at the back of the instrument to improve the accessibility for sampling. Stirrer speed is accurately controlled and maintained at +1 rpm by microcontroller.

Specifications

| GENERAL | |

| Display | 20 x 4 Line Alphanumeric LCD display with Backlit |

| Keyboard | 15 soft touch membrane keys |

| LED’s | 4 LED’s available for different status indications. 3 LED’s for Test status like Run, Alarm, End and one LED for heater on/off status. |

| Setup Data | Facility for 20 different test setups available in Routine and Sustain mode. |

| Printer | Provision for the attachment of dot-matrix printer with centronics parallel port interface available. |

| STIRRER | |

| Speed | 25 – 160 RPM + 1 RPM |

| Resolution | 1 RPM |

| Accuracy | + 1 RPM |

| Depth Adjustment | 25 mm to 40 mm, 2.25 mm + 2 |

| TEMPERATURE | |

| Range | 20 – 40 °C |

| Accuracy | + 0.2 °C |

| Temperature Control | Microprocessor Based using PT100/Semiconductor Sensor |

| SAMPLING | |

| Reaction Vessel | 1000 ml jar with stirrer pedal and basket |

| Heater | 1 KW |

| Power | 230 V ± 10%, 50 Hz. AC |

| Dimensions (L x B x H) |

330 x 300 x 660 mm (Approx.) |

| Weight | 9 Kg. (Approx.) |

| Accessories | Main Unit with Acrylic Tank and Rectangular Cover Plate Reaction Vessel – Capacity 1000 ml Round Acrylic Cover Plate with Hole and a large slit Stirrer Motor with Tightening Knob S.S. Paddle, Stirrer Shaft and Clamp, S.S Wire Mesh Basket S.S. Support Rod fitted with Acrylic Block, Mains Lead & Dust Cover Instruction Manual |

ISO Certified

ISO Certified